The SGOB 200kva Dry Transformer distribution industry is continuously evolving, driven by technological advancements and sustainability initiatives. Manufacturers are investing in research and development to enhance transformers' efficiency, durability, and safety features. This includes the use of advanced materials, such as amorphous metal cores and eco-friendly insulation systems, to improve thermal and electrical performance.

The SGOB 200kva Dry Transformer stands as a testament to the evolution and sophistication of electrical equipment within the power distribution industry. As businesses and institutions increasingly seek reliable, efficient, and environmentally friendly power solutions, the SGOB 200kva Dry Transformer has emerged as a preferred choice for a wide range of applications.

The power distribution industry is undergoing significant transformation, driven by advancements in technology, sustainability initiatives, and evolving customer demands. Transformers, as crucial components of the electrical grid, play a pivotal role in converting and distributing power efficiently. Dry-type transformers, in particular, have gained prominence due to their enhanced safety, reduced maintenance requirements, and environmental benefits compared to traditional oil-filled transformers.

SGOB 200kva Dry Transformer: Key Industry Contributions:

Efficiency and Reliability:

With a rated power capacity of 200 kilovolt-amperes (kva), the SGOB 200kva Dry Transformer offers exceptional efficiency, minimizing energy losses and reducing operational costs. Its robust construction ensures long-term reliability, enabling businesses to maintain consistent power supplies and avoid costly disruptions.

Sustainability:

The dry-type design eliminates the use of hazardous materials, such as transformer oil, reducing the environmental footprint and complying with increasingly stringent regulations on hazardous waste disposal. This contributes to overall sustainability efforts and aligns with the growing trend of adopting green technologies.

Versatility and Customization:

The SGOB 200kva Dry Transformer is versatile enough to cater to various industrial, commercial, and institutional needs. Manufacturers offer customization options, including different voltage levels, input and output configurations, and mounting arrangements, enabling end-users to tailor the transformer to their specific requirements.

Compliance and Safety:

The transformer complies with international standards and regulations, ensuring its safety and reliability. Rigorous testing and certification processes verify its compliance with industry standards, including those related to electromagnetic compatibility (EMC), short-circuit withstand capabilities, and thermal performance.

Applications Across Industries:

Industrial: In manufacturing plants, mining operations, and other heavy-duty environments, the SGOB 200kva Dry Transformer supports machinery, equipment, and control systems, ensuring operational efficiency and productivity.

Commercial: Suitable for office buildings, retail stores, healthcare facilities, and other commercial establishments, the transformer provides a stable power supply for appliances, lighting, HVAC systems, and other critical infrastructure.

Institutional: Perfect for educational institutions, government buildings, and other public facilities, the transformer ensures reliable power for essential services, enhancing safety and operational efficiency.

Industry Trends and Innovations:

The power distribution industry is continuously evolving, driven by technological advancements and sustainability initiatives. Manufacturers are investing in research and development to enhance transformers' efficiency, durability, and safety features. This includes the use of advanced materials, such as amorphous metal cores and eco-friendly insulation systems, to improve thermal and electrical performance.

Moreover, the integration of smart grid technologies and the Internet of Things (IoT) is transforming the industry. Remote monitoring, diagnostics, and predictive maintenance capabilities enable manufacturers and end-users to optimize transformer performance, reduce downtime, and extend their lifespan.

PRODUCT FEATURES

The epoxy resin cast 200kva Dry Transformer produced by Shanghai Industrial Transformer Co., Ltd. is developed and designed in cooperation with Shenyang Transformer Research Institute by introducing advanced foreign technology. The product reliability index has reached the international advanced level.

SGOB 200kva Dry Transformer is safe, flame-retardant and fire-proof, pollution-free, and can be directly installed in the load center. It is maintenance-free, easy to install, has low comprehensive operating cost, low loss, good moisture-proof performance, can operate normally at 100% humidity, and can be put into operation without pre-drying after shutdown. It has low partial discharge, low noise, strong heat dissipation function, and can operate at 150% rated load under forced air cooling conditions.

SGOB 200kva Dry Transformer are now widely used in high-rise buildings, commercial centers, airports, stations, docks, subways, factories, underground distribution stations, offshore oil drilling platforms, power plants and other places with harsh environments and use conditions.

Main materials and features

The coil uses F-class insulated copper wire as conductor and glass fiber and epoxy resin composite material as insulation. Its expansion coefficient is close to that of copper conductor and has good impact resistance, temperature change resistance and crack resistance. All components of glass fiber and epoxy resin are self-extinguishing and will not continue to burn. At the same time, the high-voltage coil is cast with epoxy resin under 1mbar vacuum state, and there are no bubbles inside the coil, ensuring that the partial discharge of the coil is small. At the same time, the loss of the transformer is effectively reduced.

The iron core of the transformer is made of 30EH120 series of high-permeability cold-rolled silicon steel sheets with orderly grain orientation imported from Nippon Steel, Japan, with 45° full-bevel joints and four-level step-by-step stacking. The surface of the iron core is sealed with insulating resin paint to prevent moisture and rust, and the two clamps and fasteners have anti-corrosion protective layers. The entire iron core adopts a non-stacked iron yoke and steel pull plate structure, which effectively reduces no-load loss, no-load current and iron core noise.

For low voltage and high current coils, the short circuit stress is large when short circuit occurs, and the number of low voltage turns is small. The larger the low voltage current is, the more prominent the problem of unstable ampere-turns will be when the wire winding type is used. The heat dissipation problem also needs to be considered. At this time, the use of foil winding for low voltage can better solve the above problems. First of all, foil products do not have axial turns and axial winding spiral angles. The ampere-turns of high and low voltage windings are balanced, and the axial stress of the transformer is small when short circuit occurs. Secondly, due to its thin insulation, multi-layer air ducts can be set at will in the process, and the heat dissipation problem is also better solved. The internal welding of the coil adopts xenon protection welding on the fully automatic foil winding machine, which has high precision, low welding resistance, and no external welding process. DMD insulation is used between the winding layers, and the ends are sealed and cured with resin after winding.

The cross-flow top-blowing cooling fan is adopted, which has the characteristics of low noise, high wind pressure, beautiful appearance, etc., and enhances the overload capacity of the transformer. The temperature control adopts an intelligent temperature controller to improve the safety and reliability of the transformer operation.

PRODUCT DESCRIPTION

Epoxy resin insulated dry type transformer is very safe product. It can be directly installed in the load center. It works well in the 100% humidity environment without pre-drying. It has been widely used in the constructions field, commercial center, airport, station, port, subway, factory, underground power distribution station, offshore oil drilling platform, power plant etc.

PRODUCT FEATURES

● Fire-resistant

● Moisture resistance

● Easy maintenance and installation

● Running well during rough environment conditions

● Non-polluting product

● Low loss during the comprehensive operation

PARAMETERS

| MODEL |

NO LOAD LOSS (W) |

LOAD LOSS (120%) |

IMPENDENCE (%) |

NOLOAD CURRENT (%) |

NOISE LEVEL (Lpa) dB |

WEIGHT (KG) |

| SC(B)10-30/10 | 205 | 750 | 4 | 2.3 | 57 | 290 |

| SC(B)10-50/10 | 285 | 1060 | 2.2 | 57 | 360 | |

| SC(B)10-80/10 | 380 | 1460 | 1.7 | 59 | 590 | |

| SC(B)10-100/10 | 410 | 1670 | 1.7 | 59 | 640 | |

| SC(B)10-125/10 | 470 | 1960 | 1.5 | 60 | 670 | |

| SC(B)10-160/10 | 550 | 2250 | 1.5 | 60 | 870 | |

| SC(B)10-200/10 | 650 | 2680 | 1.3 | 61 | 1040 | |

| SC(B)10-250/10 | 740 | 2920 | 1.3 | 61 | 1220 | |

| SC(B)10-315/10 | 880 | 3670 | 1.1 | 63 | 1470 | |

| SC(B)10-400/10 | 1000 | 4220 | 1.1 | 63 | 1760 | |

| SC(B)10-500/10 | 1180 | 5170 | 1.1 | 64 | 2050 | |

| SC(B)10-630/10 | 1300 | 6310 | 6 | 0.9 | 65 | 2360 |

| SC(B)10-800/10 | 1540 | 7360 | 0.9 | 65 | 2730 | |

| SC(B)10-1000/10 | 1750 | 8610 | 0.9 | 65 | 3270 | |

| SC(B)10-1250/10 | 2030 | 10260 | 0.9 | 67 | 3840 | |

| SC(B)10-1600/10 | 2700 | 12400 | 0.9 | 68 | 4920 | |

| SC(B)10-2000/10 | 3000 | 15300 | 0.7 | 70 | 5780 | |

| SC(B)10-2500/10 | 3500 | 18180 | 0.7 | 71 | 6600 | |

| SC(B)10-3150/10 | 4000 | 18800 | 0.5 | 71 | 7800 | |

| SC(B)10-4000/10 | 4700 | 22000 | 0.5 | 76 | 10000 |

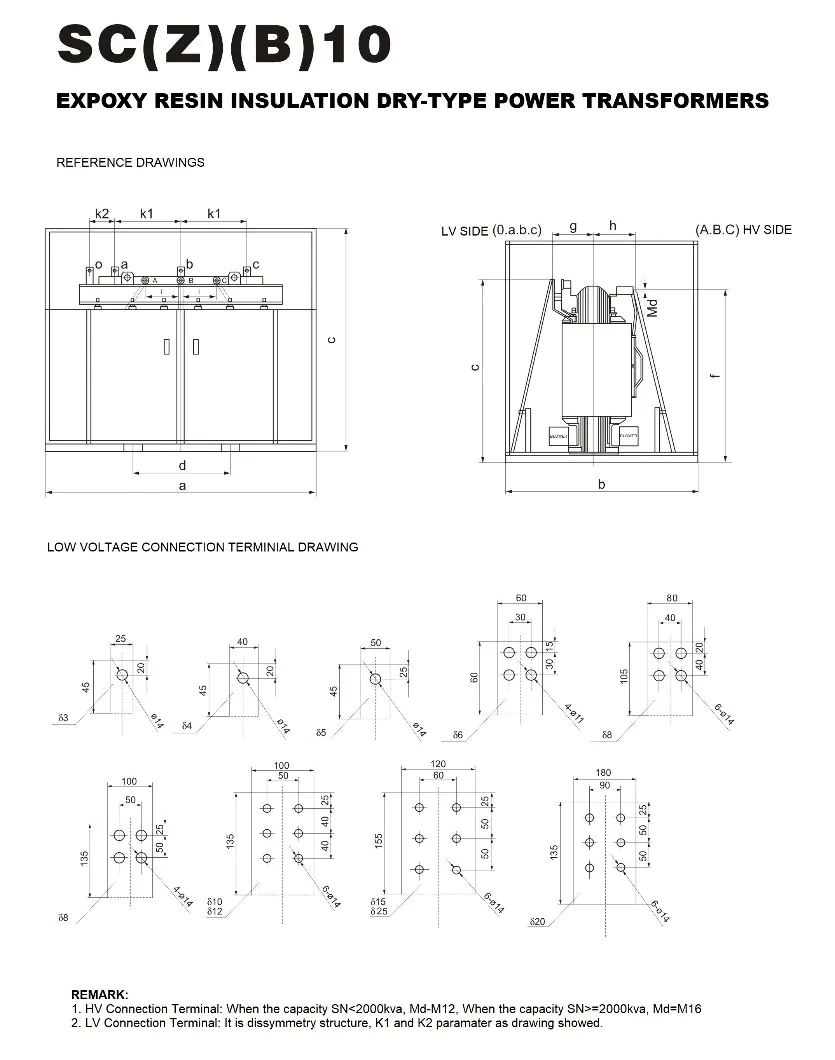

| MODEL | DIMENSION(MM) | |||||||||

| a | b | c | d | e | f | g | h | K1 | K2 | |

| SC(Z)(B) 10-30/10 | 1120 | 850 | 1100 | 400 | 750 | 640 | 290 | 260 | 270 | 135 |

| SC(Z)(B) 10-50/10 | 1170 | 850 | 1160 | 400 | 810 | 700 | 310 | 270 | 290 | 145 |

| SC(Z)(B)10-80/10 | 1210 | 900 | 1240 | 450 | 890 | 760 | 320 | 280 | 290 | 145 |

| SC(Z)(B)10-100/10 | 1240 | 900 | 1280 | 450 | 940 | 880 | 320 | 275 | 295 | 142.5 |

| SC(Z)(B)10-125/10 | 1270 | 950 | 1330 | 550 | 980 | 920 | 325 | 280 | 310 | 155 |

| SC(Z)(B)10-160/10 | 1310 | 1100 | 1360 | 550 | 1010 | 960 | 305 | 260 | 315 | 157.5 |

| SC(Z)(B)10-200/10 | 1350 | 1140 | 1400 | 660 | 1050 | 980 | 310 | 265 | 340 | 170 |

| SC(Z)(B)10-250/10 | 1420 | 1210 | 1430 | 660 | 1075 | 1010 | 300 | 255 | 355 | 177.5 |

| SC(Z)(B)10-315/10 | 1460 | 1250 | 1460 | 660 | 1100 | 1050 | 305 | 260 | 365 | 182.5 |

| SC(Z)(B)10-400/10 | 1520 | 1280 | 1520 | 660 | 1165 | 1090 | 315 | 270 | 375 | 187.5 |

| SC(Z)(B)10-500/10 | 1530 | 1320 | 1580 | 660 | 1205 | 1150 | 320 | 275 | 385 | 182.5 |

| SC(Z)(B)10-630/10 | 1670 | 1350 | 1630 | 660 | 1280 | 1200 | 325 | 280 | 430 | 215 |

| SC(Z)(B)10-800/10 | 1680 | 1350 | 1650 | 820 | 1300 | 1220 | 340 | 295 | 445 | 222.5 |

| SC(Z)(B)10-1000/10 | 1770 | 1420 | 1750 | 820 | 1390 | 1310 | 345 | 300 | 465 | 232.5 |

| SC(Z)(B)10-1250/10 | 1880 | 1530 | 1790 | 820 | 1430 | 1350 | 355 | 310 | 485 | 242.5 |

| SC(Z)(B)10-1600/10 | 1960 | 1530 | 1860 | 1070 | 1520 | 1420 | 375 | 330 | 510 | 255 |

| SC(Z)(B)10-2000/10 | 2000 | 1620 | 1960 | 1070 | 1600 | 1500 | 395 | 350 | 510 | 255 |

| SC(Z)(B)10-2500/10 | 2100 | 1680 | 2040 | 1070 | 1680 | 1560 | 425 | 380 | 550 | 275 |

| SC(Z)(B)10-3150/10 | 2240 | 1750 | 2150 | 1070 | 1800 | 1660 | 460 | 410 | 580 | 290 |

| SC(Z)(B) 10-4000/10 | 2370 | 1840 | 2310 | 1070 | 1960 | 1800 | 500 | 450 | 630 | 315 |

| MODEL | CAPACITY (KVA) |

LENGTH (MM) |

WIDTH (MM) |

HEIGHT (MM) |

LONGITUDINAL (MM) | HORIZONTAL (MM) | WEIGHT (KG) |

| SC(Z)(B) 10-30/10 | 30 | 770 | 500 | 750 | 400 | 450 | 285 |

| SC(Z)(B) 10-50/10 | 50 | 820 | 500 | 810 | 400 | 450 | 330 |

| SC(Z)(B)10-80/10 | 80 | 860 | 550 | 890 | 450 | 500 | 465 |

| SC(Z)(B)10-100/10 | 100 | 890 | 650 | 940 | 450 | 600 | 530 |

| SC(Z)(B)10-125/10 | 125 | 920 | 650 | 980 | 550 | 600 | 640 |

| SC(Z)(B)10-160/10 | 160 | 960 | 800 | 1010 | 550 | 750 | 760 |

| SC(Z)(B)10-200/10 | 200 | 1000 | 800 | 1050 | 660 | 750 | 905 |

| SC(Z)(B)10-250/10 | 250 | 1070 | 900 | 1075 | 660 | 850 | 1085 |

| SC(Z)(B)10-315/10 | 315 | 1110 | 900 | 1100 | 660 | 850 | 1175 |

| SC(Z)(B)10-400/10 | 400 | 1170 | 900 | 1165 | 660 | 850 | 1460 |

| SC(Z)(B) 10-500/10 | 500 | 1180 | 970 | 1205 | 660 | 920 | 1670 |

| SC(Z)(B) 10-630/10 | 630 | 1320 | 1000 | 1280 | 660 | 950 | 1890 |

| SC(Z)(B)10-800/10 | 800 | 1325 | 1000 | 1300 | 820 | 950 | 2320 |

| SC(Z)(B)10-1000/10 | 1000 | 1420 | 1180 | 1390 | 820 | 950 | 2800 |

| SC(Z)(B)10-1250/10 | 1250 | 1530 | 1320 | 1430 | 820 | 1270 | 3255 |

| SC(Z)(B)10-1600/10 | 1600 | 1610 | 1320 | 1520 | 1070 | 1270 | 4115 |

| SC(Z)(B) 10-2000/10 | 2000 | 1650 | 1500 | 1600 | 1070 | 1450 | 4690 |

| SC(Z)(B)10-2500/10 | 2500 | 1750 | 1550 | 1680 | 1070 | 1500 | 5620 |

| SC(Z)(B) 10-3150/10 | 3150 | 1890 | 1550 | 1800 | 1070 | 1500 | 6850 |

| SC(Z)(B) 10-4000/10 | 4000 | 2020 | 1630 | 1960 | 1070 | 1580 | 8110 |

COMPANY PROFILE

Shanghai Industry Transformers Co., Ltd (SGOB) is a full-range supplier of electrical distribution equipment. Our products include:

● Oil-immersed transformers

● 35KV oil-immersed transformers

● Expoxy resin insulation dry-type power transformers

● Amorphous alloy distribution transformers

● Photovoltaic transformers

● Wind power transformers

● Box-style substation transformers

Our company was founded in 2007 and today has a 40,000sqm workshop and more than 200 employees. Our products are widely used in a broad range of industries such as power generation and distribution, coal production, metallurgy, oil and gas, chemicals, construction, ports, airports, railway and municipal infrastructure.

We also produce related equipment such as electrical cabinets and enclosures, switchgear boxes Currently, we are expanding our product line into other power-related areas like hot shrink connectors, electrical cables and associated mechanical equipment etc. Our goal is to build a one-stop electrical equipment and parts supply platform for our global customer base.

We rely on our strict quality control system to deliver the highest quality products. Of our 200 employees, 46 are engineers experience. Our quality system includes qualifications for:

● National Transformers Quality Supervision Center of China

● ISO-9001:2008 Quality Management System

● ISO-14001:2004 Environmental Management System

● OHSMS18000 Health and Safety System

Our Patents:

Our production and quality testing capabilities include:

● Automatic foil winding

● Digital silicone steel sheeting and slitting

● Fully automatic vacuum drying oven and varnish line

● HAEFLY partial discharge tester

● HAEFLY power analyzer

● HAEFLY harmonic analyzer

The result is a superior product of high efficiency, lower power dissipation and low noise to maximize your infrastructure investment.