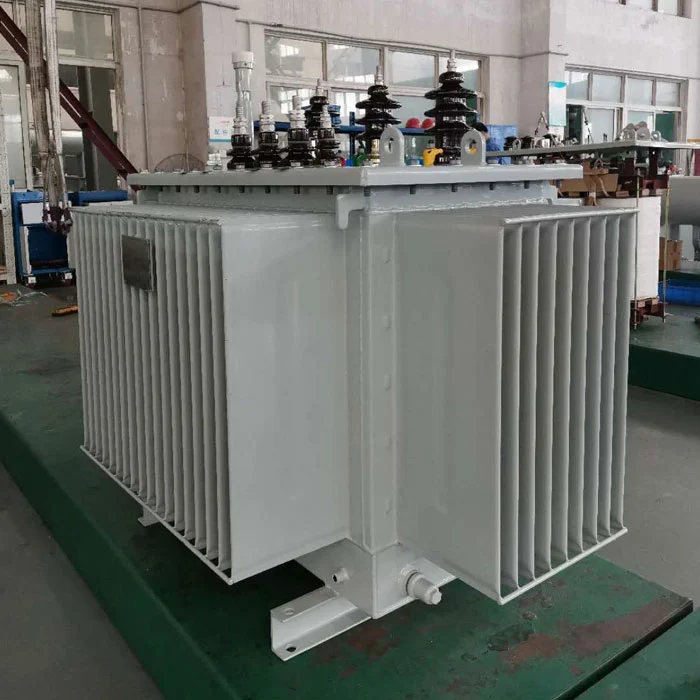

The SGOB 400kva Oil Immersed Transformer is a sophisticated piece of electrical equipment designed to meet the evolving needs of modern power distribution systems. As a leading product in the transformer industry, it combines advanced technology with robust construction to deliver unparalleled reliability, efficiency, and durability.

The SGOB 400kva Oil Immersed Transformer features a robust core and winding construction, utilizing high-quality materials to ensure optimal performance. The core is made of cold-rolled silicon steel sheets, which are stacked and laminated to minimize energy losses and enhance thermal stability. The winding is constructed using high-grade copper wire, which offers excellent electrical conductivity and heat dissipation properties.

The 400kva Oil Immersed Transformer design is a critical aspect of the transformer's performance. The transformer oil acts as a natural coolant, effectively dissipating the heat generated during operation. This helps to maintain the transformer's internal components within safe operating temperatures, reducing the risk of thermal damage. Additionally, the oil provides a layer of insulation, protecting the transformer from electrical shorts and ensuring safe operation.

The SGOB 400kva transformer is equipped with advanced protection features to ensure reliable and safe operation. These include overload and short-circuit protection, which automatically shut down the transformer in the event of a fault, preventing damage to the equipment and ensuring the safety of personnel. The transformer also meets international standards and regulations, ensuring compliance with industry requirements and providing customers with peace of mind.

In addition to its technical specifications, the SGOB 400kva Oil Immersed Transformer is designed for ease of installation and maintenance. Its compact design allows for installation in a variety of locations, including confined spaces. The transformer's oil-immersed design also simplifies maintenance, as the oil acts as a natural lubricant, reducing friction and wear on internal components.

The market for oil-immersed transformers, including the SGOB 400kva model, is driven by several factors. Growing power demand, particularly in emerging markets, is a key driver of transformer sales. As populations and economies expand, the demand for electrical power continues to rise, creating new opportunities for transformer manufacturers. Additionally, the integration of renewable energy sources, such as wind and solar, is driving the need for transformers that can handle the variable output of these sources. Oil-immersed transformers are well-suited for this task due to their robustness and adaptability.

PRODUCT FEATURES

The three-phase oil diffused distribution transformer produced by our company adopts a new insulation structure to improve the short-circuit resistance;the iron core is made of high-quality cold-rolled silicon steel sheet; the high-voltage winding is made of high-quality oxygen free copper wire and adopts multi-layer cylindrical structure;all fasteners are treated with special anti loosening treatment.

400kva Oil Immersed Transformer has the characteristics of high efficiency and low loss which can several of power consumption and operation cost,and has significant social benefits.It is a high-tech product promoted by the state.

The SGOB 400kva Oil Immersed Transformer , manufactured and supplied by a leading Chinese manufacturer, are highly advanced electrical devices engineered to meet the rigorous demands of modern power distribution systems. Crafted with precision and utilizing cutting-edge technology, these transformers are renowned for their exceptional durability, efficiency, and reliability. As a trusted supplier in China, the manufacturer offers a comprehensive range of 400kva Oil Immersed Transformer tailored to suit various applications, ensuring optimal performance and long-term value to customers worldwide.

RELIABLE STRUCTURE

Based on the traditional structure and mature technology,our company has made many improvements.

◆ The spiral coil with longitudinal oil passage has better internal heat dissipation

◆ The effective support of coil end face is improved,and the ability of short-circuit current resistance is stronger;

◆ New hoisting structure and body positioning structure are adopted to ensure more reliable in long-distance transportation and operate or

◆ We also have many unique and reliable structures to serve you;

◆ The transformer with higher performance level will have higher technical content.

HIGH QUALITY MATERIALS

A series of additional surface treatment,this smoother and has no burr Sharp angle,so that he load loss of transformer is lower and the electric.

With the improvement of performance level,the silicon steel sheet with lower unit loss is used to reduce the no-load loss of transformer.

Choose high quality laminated wood insulation,never crack,even under the action of short-circuit current.

High quality rubber sealing material is selected to effectively prevent

All raw materials have passed the quality inspection,and all raw material manufacturers have passed the strict examination according to the national standard IS09000.

OUR THREE PHASE OIL IMMERSED TRANSFORMERS

● New insulating structure to improve the anti-short circuit ability

● High-quality cold-rolled silicon steel iron core

● Selected high-quality oxygen-free copper wire

● Multi-layer cylindrical structure high-voltage windings

● Special anti-loose treatment for all of the fasteners.

PARAMETERS

| MODEL |

CAPACITY (KVA) |

HV (KV) |

LV (KV) |

NO LOAD LOSS (KW) |

IMPENDENCE (%) |

WEIGHT (KG) |

DIMENSION (L*W*H MM) |

| S11-M-30/10 | 30 | 6-20 | 0.2-0.4 | 0.10 | 4 | 325 | 750*470*930 |

| S11-M-50/10 | 50 | 0.13 | 4 | 420 | 800*490*1000 | ||

| S11-M-630/10 | 63 | 0.15 | 4 | 470 | 840*500*1010 | ||

| S11-M-80/10 | 80 | 0.18 | 4 | 540 | 870*510*1130 | ||

| S11-M-100/10 | 100 | 0.20 | 4 | 605 | 890*520*1140 | ||

| S11-M-125/10 | 125 | 0.24 | 4 | 680 | 920*590*1150 | ||

| S11-M-160/10 | 160 | 0.27 | 4 | 790 | 1110*580*1170 | ||

| S11-M-200/10 | 200 | 0.33 | 4 | 930 | 1160*620*1225 | ||

| S11-M-250/10 | 250 | 0.40 | 4 | 1100 | 1230*660*1270 | ||

| S11-M-315/10 | 315 | 0.48 | 4 | 1250 | 1250*680*1300 | ||

| S11-M-400/10 | 400 | 0.57 | 4 | 1550 | 1380*750*1380 | ||

| S11-M-500/10 | 500 | 0.68 | 4 | 1820 | 1430*770*1420 | ||

| S11-M-630/10 | 630 | 0.81 | 4.5 | 2065 | 1560*865*1480 | ||

| S11-M-800/10 | 800 | 0.98 | 4.5 | 2510 | 1620*880*1520 | ||

| S11-M-1000/10 | 1000 | 1.15 | 4.5 | 2890 | 1830*1070*1540 | ||

| S11-M-1250/10 | 1250 | 1.36 | 4.5 | 3425 | 1850*1100*1660 | ||

| S11-M-1600/10 | 1600 | 1.64 | 4.5 | 4175 | 1950*1290*1730 | ||

| S11-M-2000/10 | 2000 | 2.05 | 4.5 | 4510 | 2090*1290*1760 | ||

| S11-M-2500/10 | 2500 | 2.50 | 5.5 | 5730 | 2140*1340*1910 | ||

| S11-M-3150/10 | 3150 | 2.80 | 5.5 | 7060 | 2980*2050*2400 |

COMPANY PROFILE

Shanghai Industry Transformers Co., Ltd (SGOB) is a full-range supplier of electrical distribution equipment. Our products include:

● Oil-immersed transformers

● 35KV oil-immersed transformers

● Expoxy resin insulation dry-type power transformers

● Amorphous alloy distribution transformers

● Photovoltaic transformers

● Wind power transformers

● Box-style substation transformers

Our company was founded in 2007 and today has a 40,000sqm workshop and more than 200 employees. Our products are widely used in a broad range of industries such as power generation and distribution, coal production, metallurgy, oil and gas, chemicals, construction, ports, airports, railway and municipal infrastructure.

We also produce related equipment such as electrical cabinets and enclosures, switchgear boxes Currently, we are expanding our product line into other power-related areas like hot shrink connectors, electrical cables and associated mechanical equipment etc. Our goal is to build a one-stop electrical equipment and parts supply platform for our global customer base.

We rely on our strict quality control system to deliver the highest quality products. Of our 200 employees, 46 are engineers experience. Our quality system includes qualifications for:

● National Transformers Quality Supervision Center of China

● ISO-9001:2008 Quality Management System

● ISO-14001:2004 Environmental Management System

● OHSMS18000 Health and Safety System

Our Patents:

Our production and quality testing capabilities include:

● Automatic foil winding

● Digital silicone steel sheeting and slitting

● Fully automatic vacuum drying oven and varnish line

● HAEFLY partial discharge tester

● HAEFLY power analyzer

● HAEFLY harmonic analyzer

The result is a superior product of high efficiency, lower power dissipation and low noise to maximize your infrastructure investment.